Grand Willys Project

-

Pato

- Posts: 103

- Joined: Thu Sep 23, 2010 2:12 am

- Location: Warrnambool

Re: Grand Willys Project

Wow that looks great

- zuffen

- Senior Member

- Posts: 1926

- Joined: Fri Jan 28, 2011 7:45 pm

- Location: Sydney

Re: Grand Willys Project

Have you got the cab home yet, so you can start assembly?

Never argue with an idiot, they will drag you down to their level and beat you with experience.

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

Not yet. I have to time it for when my wife has a RDO and the next one it not until Good Friday, when they wont be open!

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

- zuffen

- Senior Member

- Posts: 1926

- Joined: Fri Jan 28, 2011 7:45 pm

- Location: Sydney

Re: Grand Willys Project

Well that wasn't very well planned.

Pity as I'm really looking forward to seeing it come together.

No doubt you are as well. Maybe just a little more than me!

No doubt you will wrap the bits that can be damaged and get all together without damage.

Pity as I'm really looking forward to seeing it come together.

No doubt you are as well. Maybe just a little more than me!

No doubt you will wrap the bits that can be damaged and get all together without damage.

Never argue with an idiot, they will drag you down to their level and beat you with experience.

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

I've just asked if we can pick it up on Tuesday after Easter, as Lisa gets that day too. Fingers crossed.

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

- big woody

- Posts: 386

- Joined: Fri Feb 18, 2005 11:15 pm

- Location: Perth

Re: Grand Willys Project

outstanding. 280 pages that have a been a pure pleasure to follow and read.

Your work redefines 1st class without a doubt

Your work redefines 1st class without a doubt

Cheers

Big Woody

I'm not smart but can lift heavy things

Big Woody

I'm not smart but can lift heavy things

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

Wow, thank you mate.

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

- zuffen

- Senior Member

- Posts: 1926

- Joined: Fri Jan 28, 2011 7:45 pm

- Location: Sydney

Re: Grand Willys Project

Well, did you get the cab home?

Never argue with an idiot, they will drag you down to their level and beat you with experience.

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

Not Tuesday after Easter yet!

Of coarse rain is now forecast for that day.

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

Doing anything I can think of to help speed up putting it back together and then getting it out of the workshop at the end!

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

- zuffen

- Senior Member

- Posts: 1926

- Joined: Fri Jan 28, 2011 7:45 pm

- Location: Sydney

Re: Grand Willys Project

Of course.

I was a week early.

This will be long slow Easter. Sorry.

I was a week early.

This will be long slow Easter. Sorry.

Never argue with an idiot, they will drag you down to their level and beat you with experience.

- zuffen

- Senior Member

- Posts: 1926

- Joined: Fri Jan 28, 2011 7:45 pm

- Location: Sydney

Re: Grand Willys Project

Is it time now?

Never argue with an idiot, they will drag you down to their level and beat you with experience.

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

We got 60mm of rain in 24 hours when we were supposed to pick it up!

Seeing I was taking bare metal parts up there on the roof and trailer as well, it didn't go ahead.

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

- Sly Fox

- Senior Member

- Posts: 1923

- Joined: Sat Apr 24, 2010 7:10 pm

- Location: Castle Hill, NSW

Re: Grand Willys Project

Good to see your keeping busy Marcus, a place for everything and everything in its place.

51 Dodge Custom & 63 EH Ute - Dare to be different

- Gojeep

- Old Hand

- Posts: 7219

- Joined: Mon Jan 07, 2008 1:24 pm

- Location: Eastern Suburbs of Melbourne

- Contact:

Re: Grand Willys Project

I wanted to replace the formply floor I had used with something longer lasting and harder wearing. After much research I came upon Compact Laminate board and the manufacturer said it would be perfect for what I going to use it for, even though I could be the first in this application! The core of a compact laminate is made up of several layers of Kraft paper that are saturated in phenolic resin. The top and bottom layer is a sheet of melamine impregnated with a patterned paper. Then pressed at 1000psi and 160*C/320*F in a large press to cure. Had it custom made to my measurements and had it freighted from interstate.

Unfortunately they did not tell me that compared to the formply, which was 50% thicker than the laminate, it was double the weight! 17mm formply weighed in at 20kg/44lbs and the laminate at 44kg/97lbs! I know I'm not building a race car, but that is a lot of extra weight. So it wasn't a total lose, I came up with a different use for it.

This stuff is super tough to cut and I went through a dozen quality metal jigsaw blades. Here I am using epoxy to double the edge and fit around a worn out desk top. Used up most the off cut to do this, so there was little wastage.

Feel better now as desk was due for replacement and this worked out a bit cheaper in the end than doing that. Can't half tell this is my desk with every model, 43 in all, being either a Willys Truck or Panel of the same model as mine.

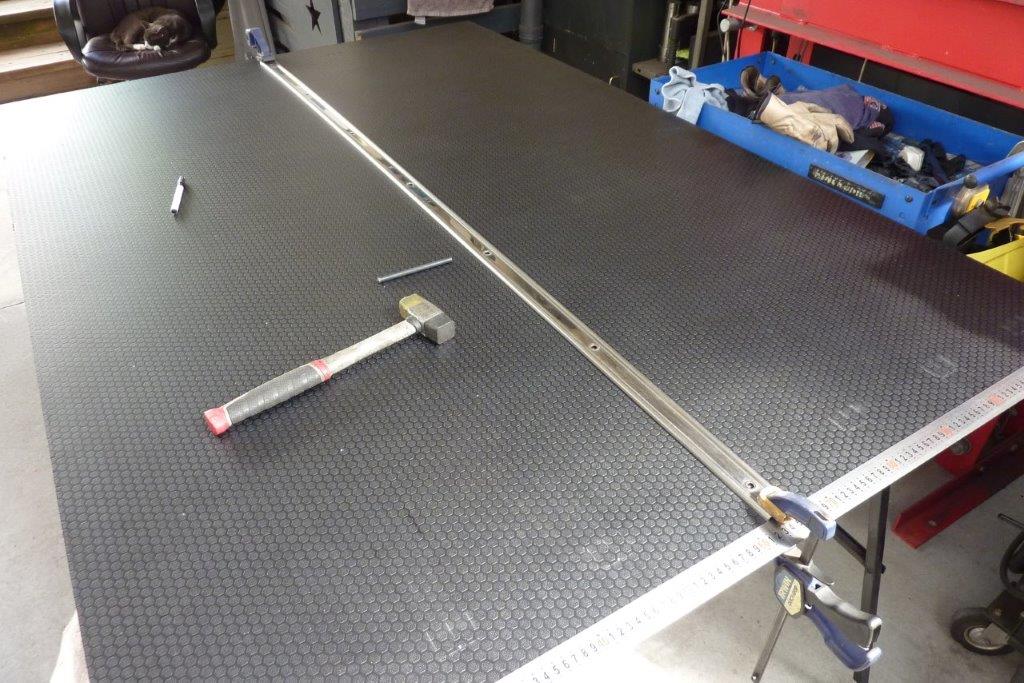

So what to use now? I really wanted to avoid a seam but my floor is wider than the normal 2440x1220mm/8'x4' sheet. I found this black patterned non slip Baltic birch plywood with just a layer of phenolic resin each side. Was a third of the price and less than half the weight too! Where the ruler lays is where I need to cut lengthwise.

I could also get it in a 3050x1524mm/10'x5' sheet. Was way more than I needed length wise and even a bit extra width wise as the photos show.

The hexagon pattern is a lot like a bed liner and very hard and tough. Used for trailer, caravan, scaffolding platforms etc.

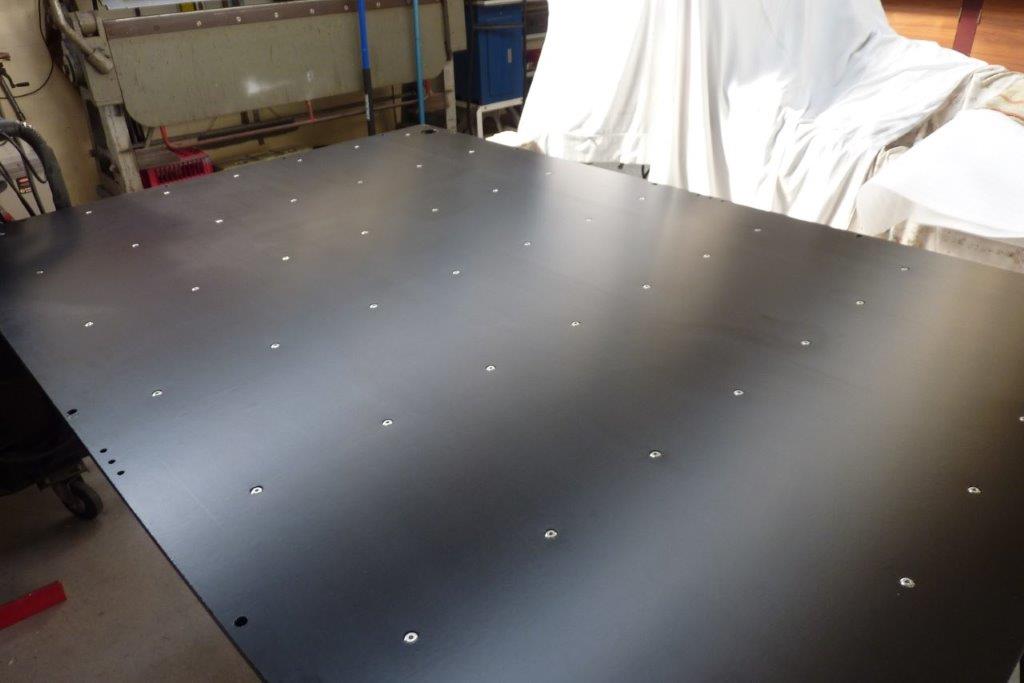

It was cut down to 1860x1288mm/73"x51" to replace the formply.

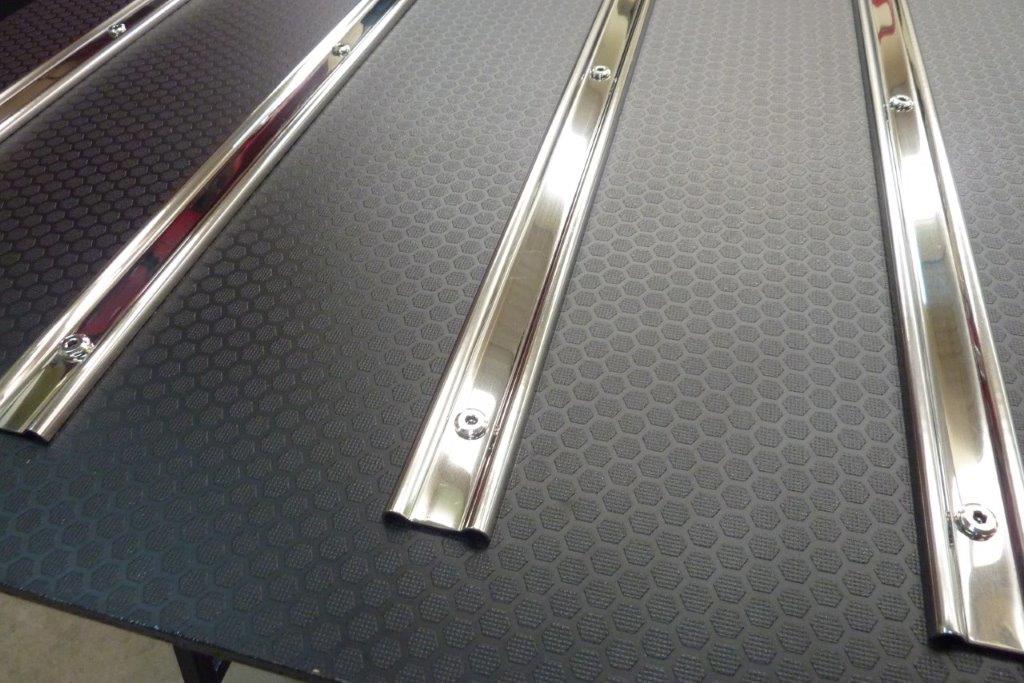

I laid down the stainless steel rub strips and used a transfer punch though the existing holes.

All the holes, which were less than 0.5mm bigger than the stainless barrel, or furniture bolts, all fitted perfectly.

The chassis and cross members were covered in automotive body mount double sided tape.

Then covered with neoprene rubber strips to isolate the board from the chassis to stop any noise and make up the difference in thickness between it and the formply.

74 holes later, which were all painted by hand as well as the cut edges to stop any moisture getting in over time, it was ready to mount.

The fasteners were all recessed into the floor for a flat finish and placed onto the chassis ready for the tray.

Marcus

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)

To try where there is little hope, is to risk failure.

Not to try at all, is to guarantee it!

____| \______\

|/¯\ |¯ |----O||||O

()_)-o-)¯¯()_)-o-)_)